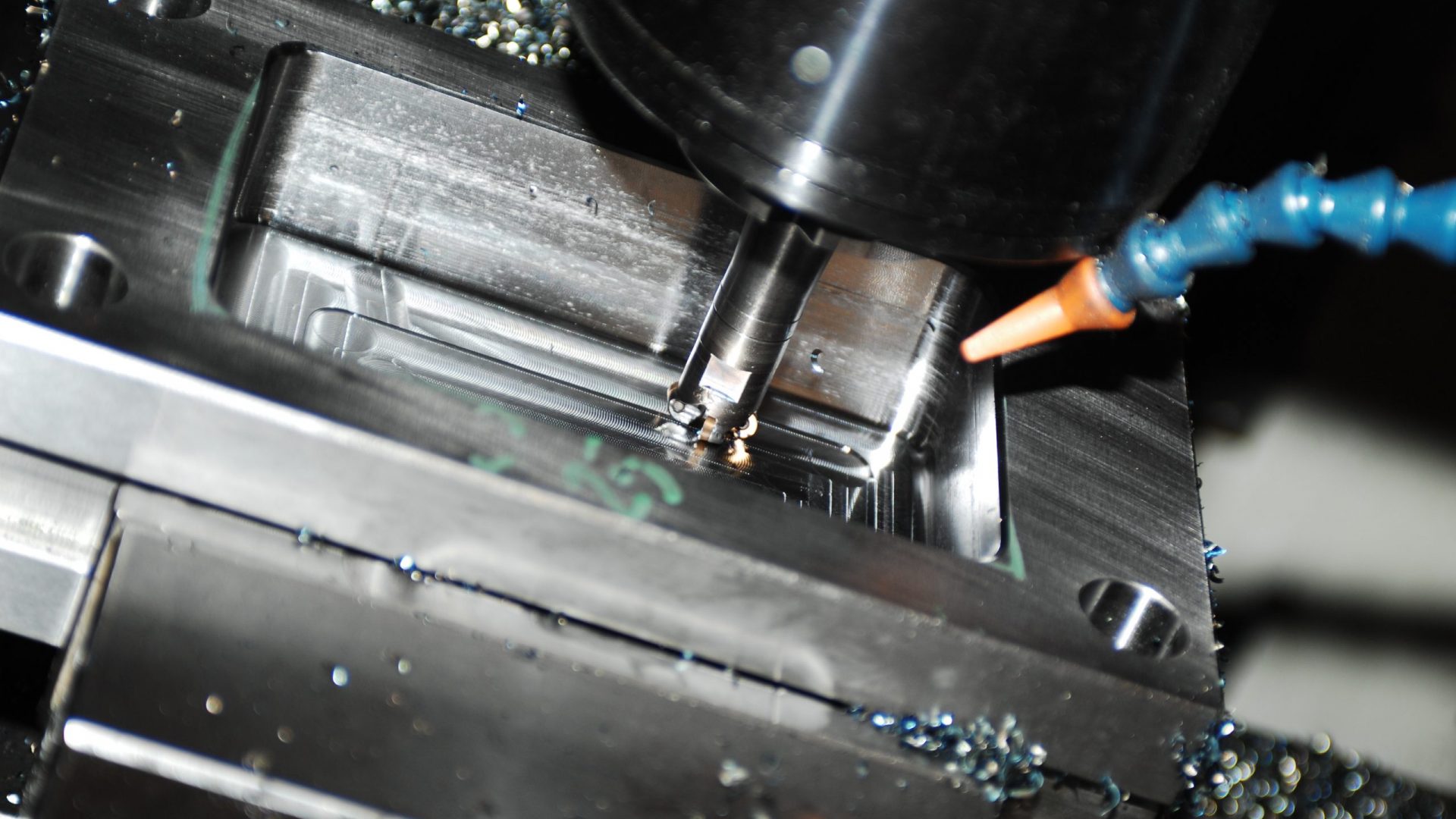

Since 1973 we are specialised in design and manufacture of plastics injection moulds. The experience gained over these years has led us to be always in step with the times and to integrate into a fast-changing, dynamic and competitive market. Our main features are technology and reliability. To make high quality moulds we use only high-grade and cretified steels.

In addition to the moulds manifacturing, we also make ordinary and extraordinary maintenance to ensure maximum efficiency and productivity.

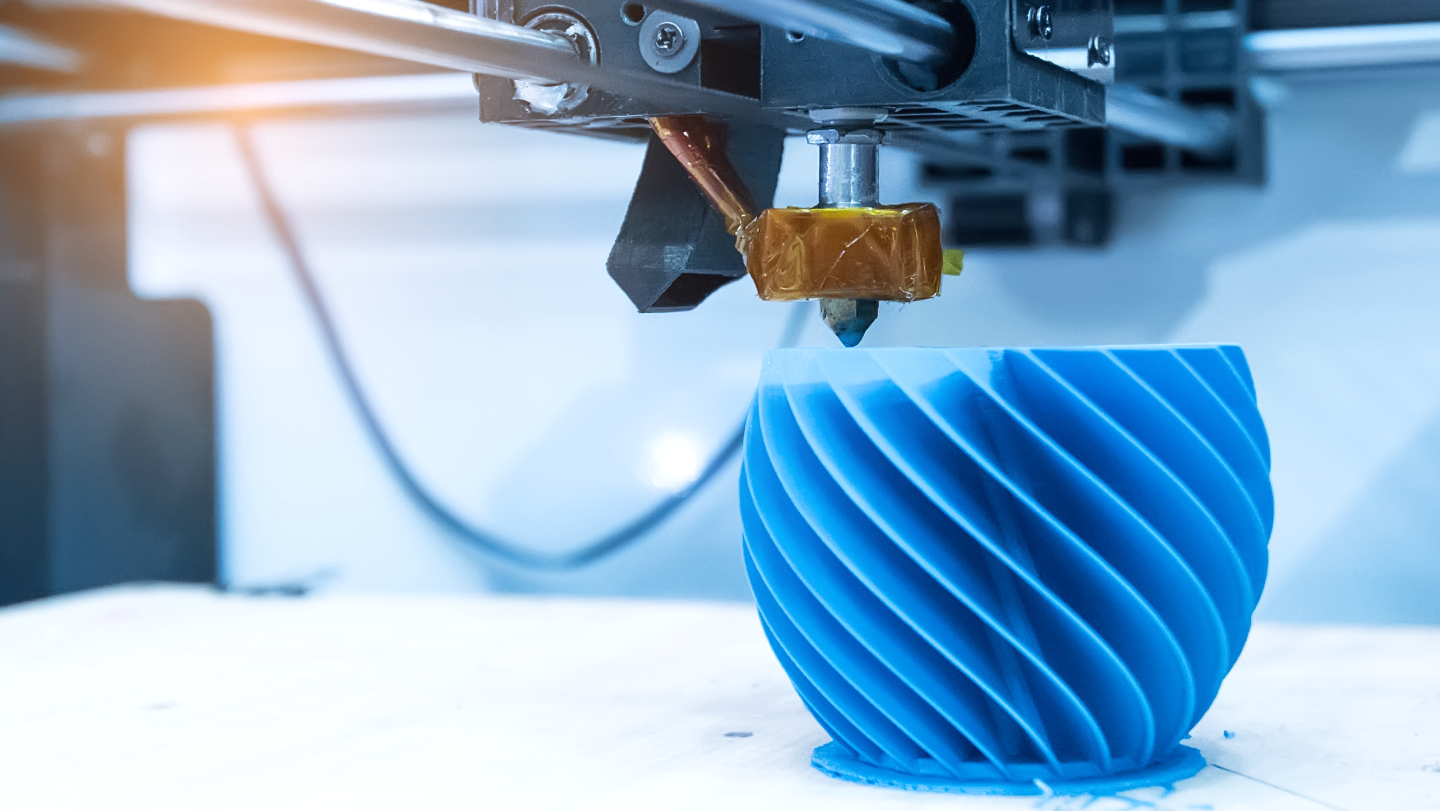

We are able to modify and repair existing moulds. Instead, we are supported by external suplliers for welding, polishing, chrome plating and heat treatments. During the project development, if necessary, we have connection with companies specialised in rapid prototyping and 3D scanning.

Our technical staff is trained and constantly updated. They work with attention and communicate with the customer to keeping him regularly informed on the evolution of the job. We use the most modern technologies for every internal processing phases and we give support to our partners in the external ones. We make this to always guarantee quality and efficiency.

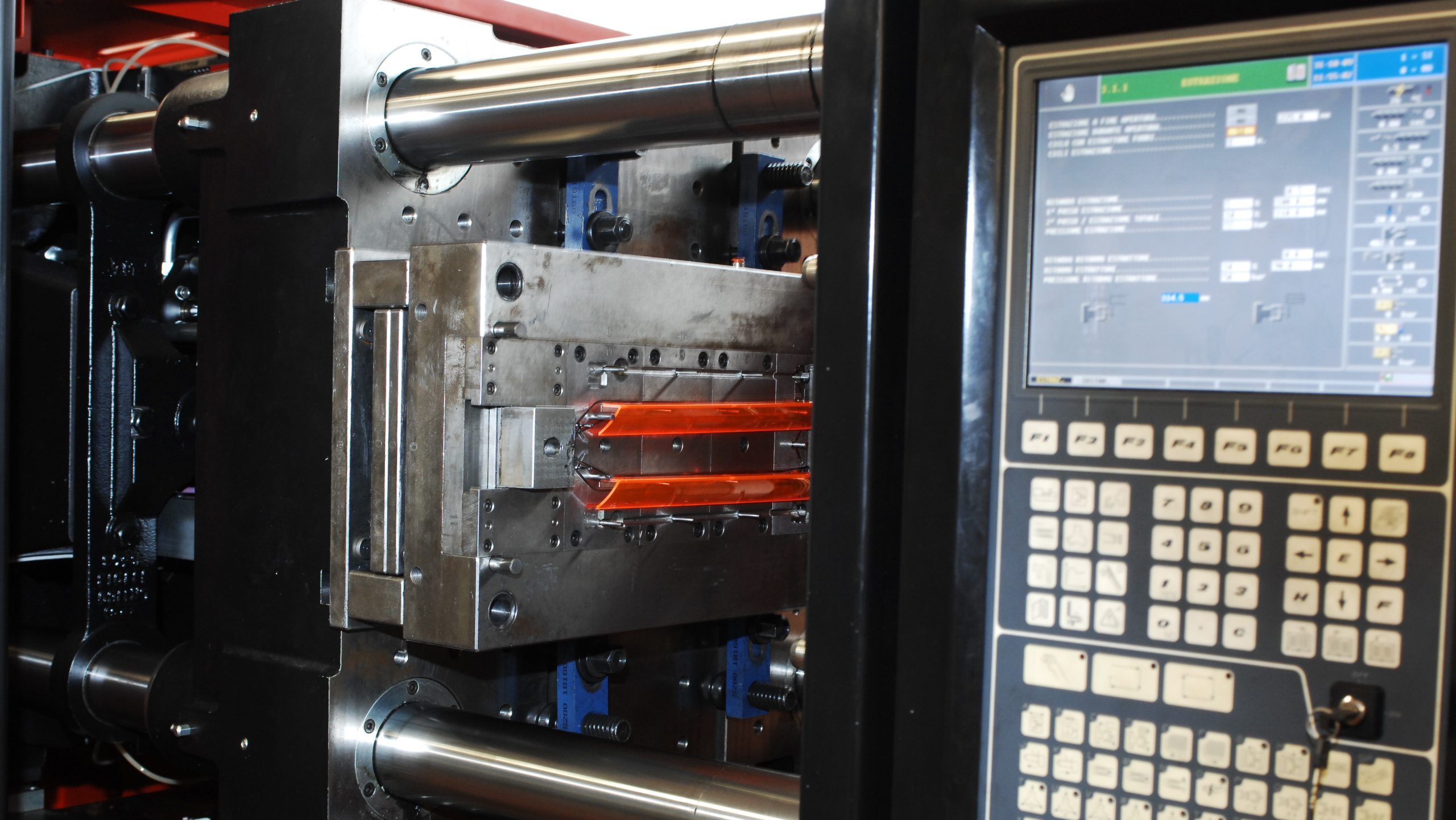

Since 1990 we are specialised in the molding of thermoplastic items. The presence of an internal workshop allows us to support the customer in all phases of the work, from the development with the mould construction, up to the production with the moulding of the finished and tested product. Thanks to the deep knowledge of the sector, we can assist the client during the choice of raw materials in order to reach the best result.

To best meet the needs of our customers we have an internal assembly line. In this way, in addition to moulding the different parts that will make up the final product, we can also assemble them to deliver the complete item to the costumer. Furthermore, if needed, we can also carry out pad printing and ultrasonic welding services.

For finishing processes such as painting, silk-screen printing and hot marking, we are supported by a selected and qualified network of partners.